What is Electronic Waste? Where Does It Go? Strategy to Minimise Impact for Manufacturers

Hedonic consumerism is killing us and the planet

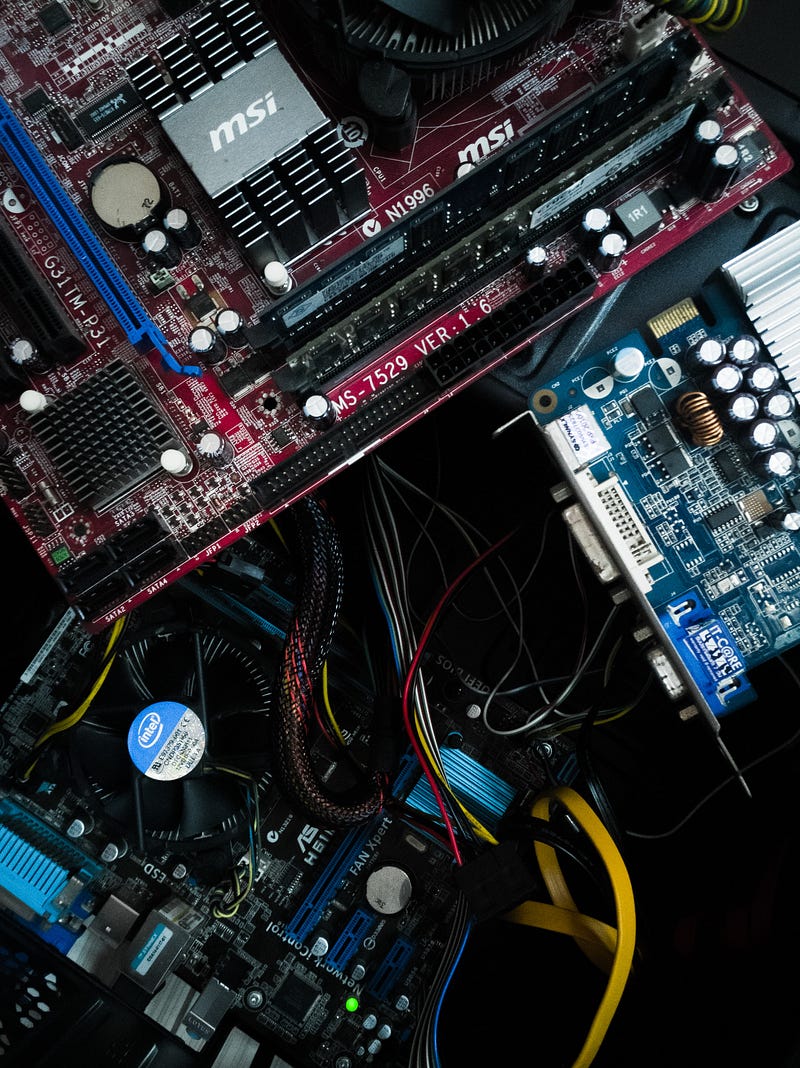

We earn more, spend more; we want more from our lives, and technology increases our living standards, making our lives easier. We have become an industrialised society depending on technology for progress. It means higher consumption of electronics and gadgets that help us sustain our existence.

Higher consumption means a higher output of electronic waste, and we have not done anything to optimise how we deal with that constant flow of hazardous materials. Currently, the consumption of electronic equipment increases by 2.5 million tons every year.

We are also constantly conditioned by manufacturers to constantly upgrade to a newer, shinier model every year, even though the rational arguments for it could be very slim. Manufacturers also add to this issue by purposefully designing products with shorter life cycles as they are for-profit corporations. The planet’s well-being tends to lose to profit when it comes to a board of directors vote.

The lack of effective repair options means consumers are also in a position to replace rather than reuse their devices. But, again, it is a lot easier for a corporation to optimise for new product development and manufacturing rather than develop a strategy for extending the current in-field device lifetime. The absence of country-wide legislation only exacerbates this issue. However, there are glimpses of hope with pro-repair movements, such as Right To Repair.

In 2019 Europe ranked as the world’s highest electronic waste generator, meaning that each person, on average, generated 16.2 kg of electronic waste per year; however, it is also the world’s biggest recycler at 42.5% of the generated waste being recycled. Compared to the United States, which recycled only 9.4% out of 13.3kg per person of electronic waste that was generated in 2019.

We do not recycle enough electronic waste

After using the electronic gadget, it becomes part of the electronic waste stream. Unfortunately, this stream is full of hazardous materials, such as mercury, brominated flame retardants (BFR), chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs). We know that these materials are harmful to our health and also when released as greenhouse gasses into the atmosphere, cause global warming and climate change.

When we do not recycle and bin the electronic waste straight into our bins destined for wasteland, the people at the sorting facility are exposed to these harmful elements. So are the people who live around dump sites, and so are their children. We also lose valuable raw materials by not recycling properly. And the government does not provide enough education on proper recycling. Country leaders should do enforcement via education and not the penalties.

The Global E-waste Monitor 2020 informs us that “In 2019, approximately 53.6 million metric tons (Mt) of e-waste (excluding PV panels) was generated, or 7.3 kg per capita. It is estimated that the amount of e-waste generated will exceed 74Mt in 2030. Thus, the global quantity of e-waste is increasing at an alarming rate of almost 2 Mt per year.”

Over 60% of consumers would switch to rivals of their preferred tech brands if they found that the manufacturer did not produce the goods sustainably, and 70% said it was difficult and expensive to repair their electronics.

The current recycling activities are not keeping pace with how much electronic waste we produce. For example, in 2019, the world registered recycling of 17.4% of electronic waste, and the fate of 82.6% and its whereabouts are unknown. We can only wonder what kind of environmental impact this might have caused.

Every electronic device has high-value metals inside, such as gold, platinum and palladium. All these metals can be separated and resold to be reused in manufacturing new electronic equipment. However, with more than 70% of electronics destined for landfills, businesses are losing out on profits. As much as 75 billion dollars worth of electronics were sent to landfills and burned. And instead, we dug holes in the planet to mine virgin metals, potentially damaging the environment even further.

Strategy for manufacturers to reduce electronic waste impact

- Manufacturers can improve returned goods efficiency as the returned goods are already manufactured products. Returned goods stream is the primary supplier of already manufactured products. They can also reach out to 3rd Party Reverse Logistics suppliers, such as TFix, to help them get faulty devices from customers, refurbish them, and either send them back to customers or re-introduce them back into the market.

- With the current documented collection and recycling rate of only 17.4%, a raw material value of 10 billion dollars is recovered in an environmentally sound way from e-waste globally, and 4 million tons of raw materials could be made available for recycling. Overall, the value of selected raw materials in e-waste in 2019 was approximately 57 billion dollars. Mining electronic waste instead of the Earth for resources will be made compulsory by governments worldwide soon, and those who start developing strategies earlier rather than later will benefit profoundly.

- Develop a circular economy, which would look like providing a leasing service in the electronic equipment industry instead of selling a product. Consumers might prefer leasing or renting the product due to lower financial investment, manufacturer-provided servicing and the ability to return the device at the end of the term. The manufacturer benefits from making their product more approachable to consumers, which leads to more sales and revenue.

- Build devices to last longer / provide software updates longer. Suppose performance is already more than “good enough” and increasingly contained by the form factor. In that case, chip designers should focus on efficiency and long-term support rather than chasing increasingly difficult new technological developments.

- Offering refurbished products within the same market or even developing countries’ markets is also a viable solution to mitigate electronic waste. When the product is exhausted within the primary market, it can be refurbished and introduced back into circulation within different market segments to further its life cycle.

Let’s mine electronic waste, not the Earth

We have more access to electronic gadgets than ever, which produces a lot more electronic waste.

Electronic waste adds to global warming and climate change, it poisons our health, and we lose a lot of valuable manufacturing materials by destroying the waste. We then mine the Earth for raw materials using environmentally unfriendly ways.

Manufacturers are on the front line of improving the reusability and recyclability of Electric and Electronic Devices (EEDs). The manufacturer can improve their electronic waste response by having an efficient returns strategy, mining their electronic waste instead of the Earth, developing a circular economy, building devices to last longer and offering refurbished goods as alternative option.